Controlling a 4-Wire Stepper Motor with an L298N Module

This detailed tutorial shows how to control a stepper motor using the L298N dual H-Bridge driver and an Arduino board. You’ll learn how to rotate the motor clockwise and counterclockwise, adjust speed, and set position using a potentiometer. Several code examples are provided for practical applications like single-step motion and knob-based control.

All wiring diagrams and Arduino code examples used in the video are available for download below this article.

🧾 Introduction

This tutorial uses a 28BYJ-48 or similar stepper motor controlled through an L298N motor driver module. The L298N supports two DC motors or one stepper motor and is ideal for robotics and motion-based projects where bidirectional and speed control are required.

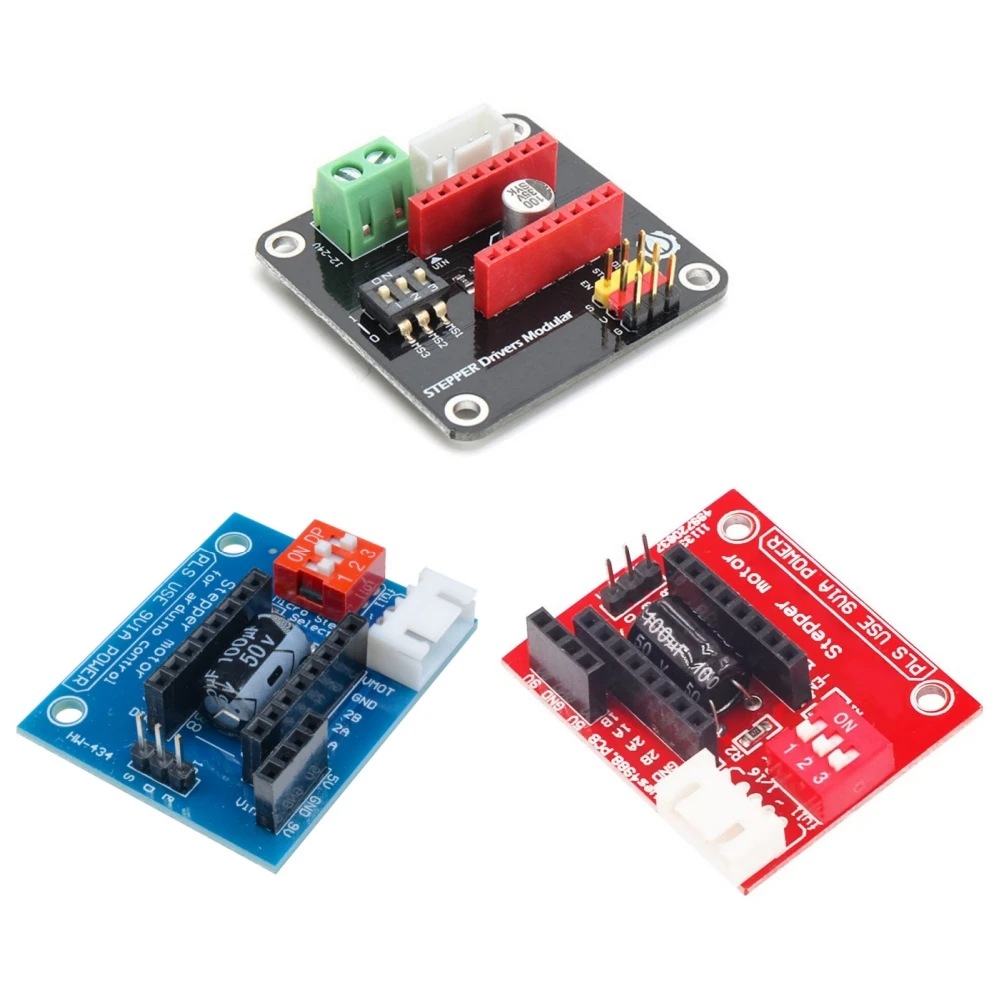

🔧 Hardware Components Explained

The video explains the following key components:

L298N driver module: Converts Arduino signals into motor-driving voltage/current

Stepper motor: Operates in precise steps for controlled motion

Potentiometer: Used for controlling speed or position

Arduino Uno: Controls everything with custom logic via uploaded sketches

The explanation covers pin functions, motor connections, and power input options.

🔌 Wiring the Circuit

The motor wires are connected to the OUT1 to OUT4 pins on the L298N. The IN1 to IN4 pins on the module connect to the Arduino’s digital pins. A potentiometer is connected to analog input (A0 or similar) for controlling speed or position.

💻 Code Example – Stepper Motor Control Using L298N and Arduino

The following Arduino sketch demonstrates how to rotate a stepper motor clockwise and counterclockwise using the L298N motor driver and the built-in Stepper library.

cppCopyEdit#include <Stepper.h>

const int stepsPerRevolution = 200; // Number of steps per full rotation

// Define motor control pins connected to L298N IN1–IN4

Stepper myStepper(stepsPerRevolution, 8, 9, 10, 11);

stepsPerRevolutionshould match the specifications of your stepper motor (commonly 200 for NEMA 17 motors).Pins 8–11 on the Arduino are connected to the L298N input pins (IN1–IN4).

cppCopyEditvoid setup() {

myStepper.setSpeed(300); // Set motor speed in RPM

Serial.begin(9600); // Start serial communication

// Enable L298N motor channels

pinMode(2, OUTPUT);

digitalWrite(2, HIGH); // EN1 enabled

pinMode(3, OUTPUT);

digitalWrite(3, HIGH); // EN2 enabled

}

setSpeed(300)sets the motor speed to 300 RPM (you can adjust this).EN1 and EN2 pins (connected to Arduino pins 2 and 3) are enabled to activate both motor channels on the L298N.

cppCopyEditvoid loop() {

Serial.println("clockwise");

myStepper.step(stepsPerRevolution); // Rotate one full revolution clockwise

delay(500);

Serial.println("counterclockwise");

myStepper.step(-stepsPerRevolution); // Rotate one full revolution counterclockwise

delay(500);

}

The motor performs one full revolution in the clockwise direction.

Then, it reverses and performs a full revolution counterclockwise.

A

500 msdelay is placed between the two motions for observation.

This code demonstrates how to alternate the direction of the stepper motor continuously, making it ideal for beginners learning bidirectional motion control.

🎬 Video Chapters

00:00 – Start

00:52 – Introduction

01:51 – Hardware Explained

10:06 – Wiring Explained

13:27 – Code Explained (1)

19:06 – Code Example (One step at a time)

19:47 – Code Example (Motor knob: position)

26:15 – Code Example (Motor knob: speed)

📥 Download Section

You’ll find all the code samples, wiring diagrams, and component links below this article. This tutorial is ideal for students, engineers, and hobbyists exploring stepper motor applications in embedded systems.

/*

* MotorKnob

* Modified by Ahmad Shamshiri for Robojax on July 20, 2019

* in Ajax, Ontario, Canada

* Watch video instructions for this code: https://youtu.be/cYTICj4DWYc

*

* A stepper motor follows the turns of a potentiometer

* (or other sensor) on analog input 0.

*

* http://www.arduino.cc/en/Reference/Stepper

* This example code is in the public domain.

*/

#include <Stepper.h>

// change this to the number of steps on your motor

#define STEPS 200

// create an instance of the stepper class, specifying

// the number of steps of the motor and the pins it's

// attached to

Stepper stepper(STEPS, 8, 9, 10, 11);

// the previous reading from the analog input

int previous = 0;

void setup() {

// set the speed of the motor to 30 RPMs

stepper.setSpeed(5);

Serial.begin(9600);

}

void loop() {

// get the sensor value

int val = analogRead(0);

int step=map(val, 0, 1023, 0, STEPS);

// move a number of steps equal to the change in the

// sensor reading

stepper.step(val - previous);

// remember the previous value of the sensor

previous = val;

}منابع و مراجع

هنوز هیچ منبعی موجود نیست.

فایلها📁

هیچ فایلی موجود نیست.

![Official Arduino Starter Kit [K000007] - 12 DIY Projects with Electronic Components & English Projects Book - Original Kit from Italy](https://m.media-amazon.com/images/I/51fPv6DsjQL._SL75_.jpg)